Danh mục sản phẩm

Hỗ trợ trực tuyến

VIDEO

Chi tiết sản phẩm

-

Bộ tự động kiểm tra giấy PC300/210 Nireco

- Mã SP:

- Giá : Liên hệ

-

Hãng : NIRECO

Xuất xứ : Japan

Model sản phẩm : PC300/210

Tình trạng : Mới 100%

Liên hệ tư vấn : 0917943068 Mr.Chiến (Zalo)

Email : chien@tmpvietnam.com

Tăng Minh Phát - Đại lý hãng NIRECO tại Việt Nam. Chuyên cung cấp những thiết bị cảm biến cho hệ thống tự động canh tâm hệ thống tự động canh biên cho những nhà máy sản xuất bao bì giấy, tôn

Bộ tự động kiểm tra giấy PC300/210 Nireco (Paper Checker )

1/ Tổng quan:

_ Dòng Paper Checker có thể được sử dụng làm máy phát hiện tờ giấy đôi cho máy ép nạp tờ giấy, cũng như máy phát hiện mối nối hoặc vết đứt. Những sản phẩm này có thể được sử dụng cho nhiều loại vật liệu bao gồm giấy, nhôm laminate, poly-laminate và nhựa.

1.1/ Ứng dụng chính của Paper Checker PC300:

+ Phát hiện các mối nối hoặc đứt gãy của web

+ Máy in quay, máy xén, máy ép màng, máy tráng, máy cuộn

+ Ngăn chặn sự chồng chéo 2 tờ

+ Máy in dạng tờ, máy cán màng

1.2/ Ứng dụng chính của Paper Checker PC210:

+ Phát hiện các mối nối hoặc đứt gãy của web

+ Máy in quay, máy xén, máy ép màng, máy tráng, máy cuốn, v.v.

+ Ngăn chặn sự chồng chéo 2 tờ

+ Máy làm hộp, máy cán màng

2/ Tính năng:

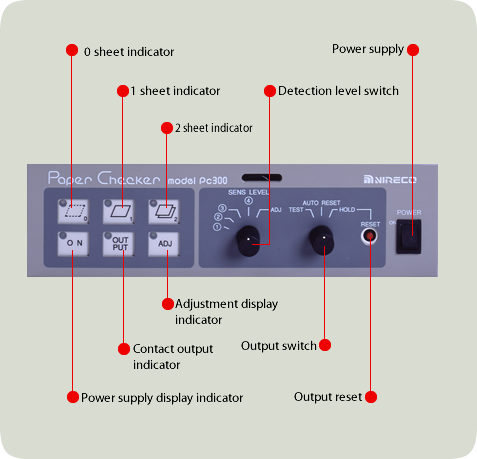

PC300

_ Paper Checker PC300 và UH300 là máy dò nạp giấy đôi được phát triển đặc biệt cho máy ép nạp giấy. Ngoài giấy, nó còn có thể được sử dụng với nhôm cán mỏng, giấy nhiều lớp, nhựa và một số vật liệu khác. Nó cũng có thể xử lý nhiều loại độ dày và độ dày đang sử dụng có thể được chọn đơn giản từ một công tắc trên bảng điều khiển để dễ dàng thay đổi. PC300 có thể phát hiện các tờ giấy đôi của bất kỳ vật liệu nào và ngăn việc nạp các tờ giấy đôi cùng một lúc do lỗi hoặc thiếu sót của người vận hành.

+ Hệ thống phát hiện không tiếp xúc

+ Không có trục trặc do hình ảnh hoặc ký tự được in

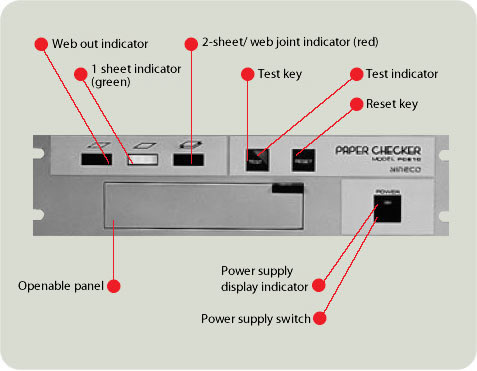

PC210

_ Paper Checker PC210 và UH200 phát hiện mối nối hoặc vết đứt của màng trong mọi quy trình của màng. Ngoài ra, nó còn phát hiện việc nạp các tờ giấy đôi bằng máy đóng bao, máy này sẽ nạp từng tờ một. Khi phát hiện sự bất thường trong mỗi ứng dụng, nó sẽ được chỉ báo trên bộ điều khiển và rơle đầu ra được kích hoạt. Tiếp điểm này làm cho còi báo động phát ra âm thanh và đèn báo cảnh báo sáng lên, từ đó thông báo cho người vận hành hoặc dừng hoạt động.

+ Phát hiện không tiếp xúc

+ Phạm vi áp dụng rộng rãi của độ dày web (tấm)

+ Tất cả các vật liệu có thể được xử lý (giấy, giấy bóng kính, lá nhôm, poly-laminate, v.v.)

+ Không có trục trặc nào xảy ra do mẫu hoặc ký tự được in.

+ Phát hiện đồng thời mối nối và đứt gãy

+ Màu sắc và vật liệu của băng nối và mối nối* không ảnh hưởng đến việc phát hiện.

(Mối nối đối đầu và mối nối chồng lên nhau khi phát hiện mối nối)

3/ Thông số kỹ thuật:

PC300(Controller), UH300(Sensor) |

|

|---|---|

Detecting method |

Non-contact detecting system |

Application |

Double-sheet detector for sheet-fed press |

Material type |

Paper, aluminum laminate, poly-laminate, plastics

|

Input |

Synchronous signal, output reset signal |

Operating speed |

15000sph (max) |

Power supply |

100 to 240V AC, 50/60Hz |

Power consumption |

10VA (max) |

Mess |

Controller 2kg,

|

Ambient temp. |

0 to 50℃ |

PC210(Controller), UH200(Sensor) |

|

|---|---|

Web splice detection |

|

Web thickness |

1μm to 0.8mm |

Splice width |

20mm or more |

Line speed |

1000m/min or less |

Inter-lock input |

a-contact, rating: 5V DC, 10mA |

Web break detection |

|

Web thickness |

50μm to 0.8mm |

Line speed |

1000m/min or less |

Double-sheet feed detection |

|

Sheet thickness |

15μm~0.8mm |

Common specifications |

|

Power supply |

100 to 240V AC, 50/60Hz |

Power consumption |

10VA |

Contact output |

C-contact

|

Weight |

Controller: 2kg

|

Cable length |

5 meter each |

Ambient temperature |

0 to +50℃ |

Tiếng Việt

Tiếng Việt English

English